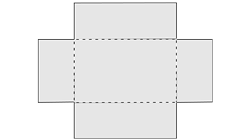

Rigid boxes start off as a flat paperboard, usually at least 800gsm thick, where it is cut and scored to its correct size. The dotted lines show where the paperboard will then be folded up.

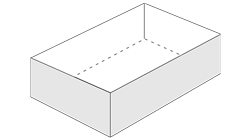

The sides of the box are folded up and secured to form the base shape of the box. Once folded, you have the basic skeleton of your packaging.

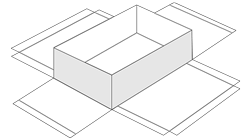

A design is printed onto a piece of paper (the wrap), gets laminated, and other add-ons such as foil stamping or embossing is also done now. The wrap is then automatically glued to the shape of the box.

The wrap covers your box tightly and brings your rigid boxes to life. Voila!